Asteroid Precision is equipped with the best systems and process controls to respond to the increasing sophistication and complexity of our customers’ products and systems.

From our manufacturing systems and verification processes through to final inspection, customers can count on us for the consistent delivery of the highest quality precision components.

Our Inspection Process

When it comes to precision parts, Asteroid Precision has over 50 years of experience working with industries that need the tightest tolerances at the best quality.

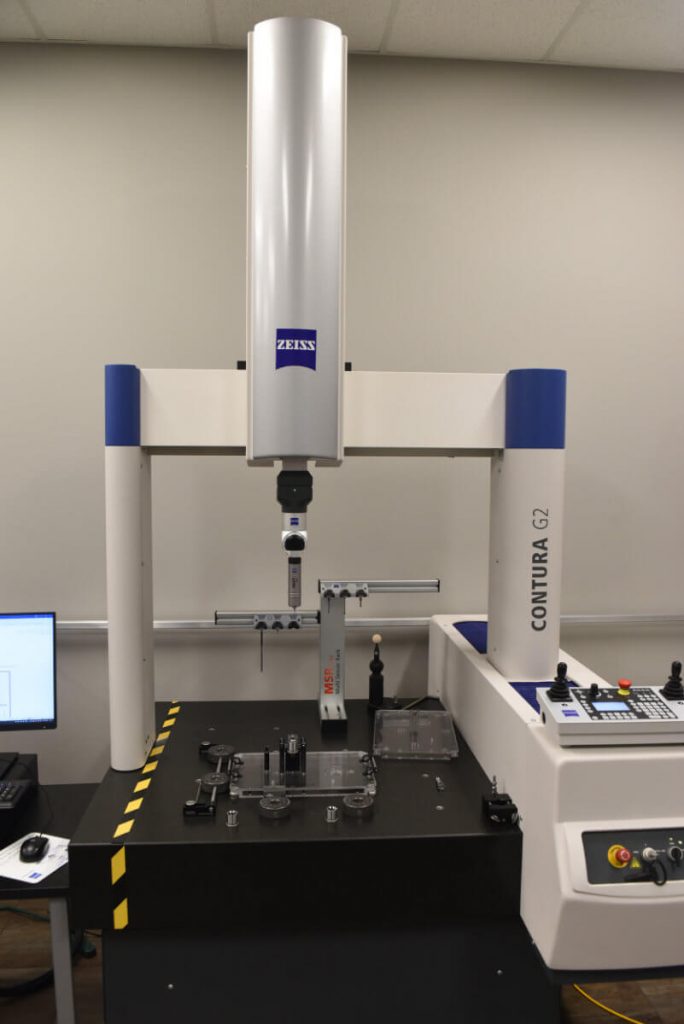

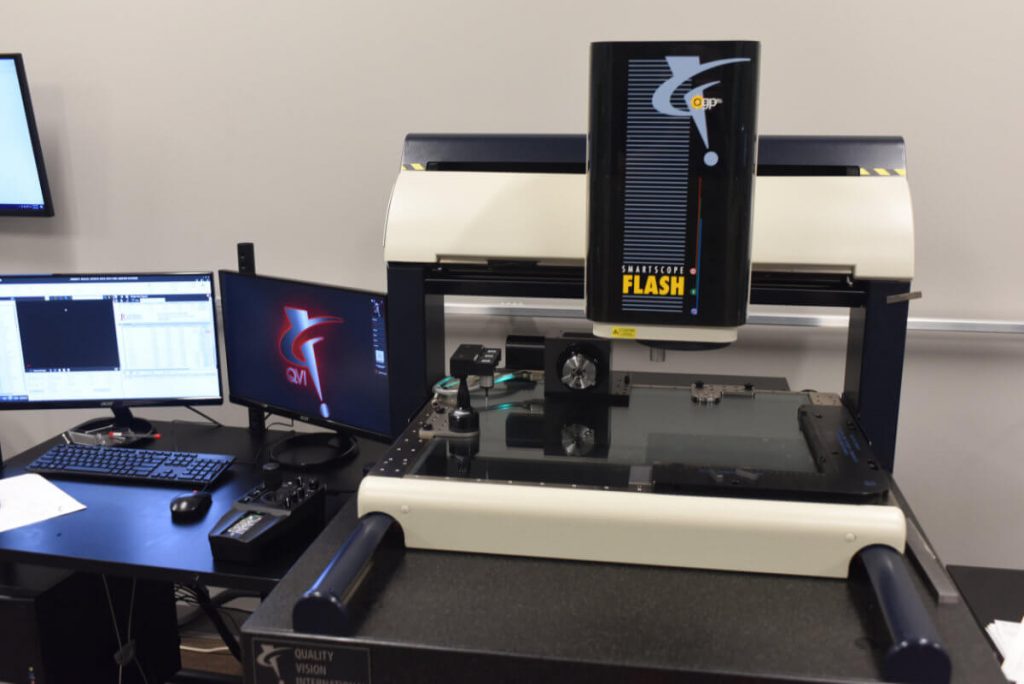

Our strict adherence to the most demanding quality ensures effective performance of our processes. We are continually investing in new technologies to improve quality and cost such as our OGP Vision System with laser scanning capabilities for measurement validation.

Our process of first article inspection is instrumental prior to starting the operation. This form of risk mitigation allows both the Operator and Quality Specialist to have a plan of action prior to production.

Additionally, we check consistency throughout the run with random component sampling. This way, if anything changes during the process, we can spot the error as it occurs, make corrections, and continue with production. This vital piece of the process ensures your project is completed to the highest degree of quality in the time we quoted.

Finally, we complete a production lot inspection to ensure your precision grinding components are finished to your specifications. Our state-of-the-art equipment, such as the MMQ 400, CS-3200, and MicroVu, allows for a detailed examination:

- Our Geometric Gauging is capable of measuring roundness and concentricity down to .00001”, ensuring you have the precise measurements you need.

- Laser micrometers deliver repeatability to .00002″ and accuracy of .00001″ with single point re-mastering.

Four Stage Quality Control

By utilizing a scheduled maintenance program for our precision grinding machines, we ensure that you are getting your work done on exceptionally well-kept equipment that can provide the detailed specifications of your project over and over again.

We use lean processes in our quality control plan to maximize our multilevel inspection process, including:

- First Article Inspection

- In-Process Inspection

- Random Sampling

- Final Production Lot Inspection

Documentation

Our strict obedience to the most demanding quality standards ensure effective performance of our processes and systems. We use data-driven methods along with quality-related processes and procedures to assure the integrity of the precision components we supply.

Quality Management Techniques:

- Production Part Approval Process Level 3 ( PPAP)

- Statistical Process Control ( SPC)

- Certificate Of Compliance ( COC)

- First Article Of Inspection (FAI)